Product Installation

Professional fiber cement board panel manufacturer

Fiber cement board panels are modified cement high pressure forming products. They have a similar service life to reinforced cement prefabricated products. They are non-load-bearing wall panels and have different usage methods. In order to use them correctly and avoid trouble and losses, this notice is specially formulated.

1. The cement board panels should be placed horizontally, the pallets should be flat, and the cement board panels must be stored indoors; when stored outdoors, they must be covered with waterproof cloth and must not be exposed to rain before installation. When transporting a single panel, two people should carry it horizontally and vertically to prevent it from breaking.

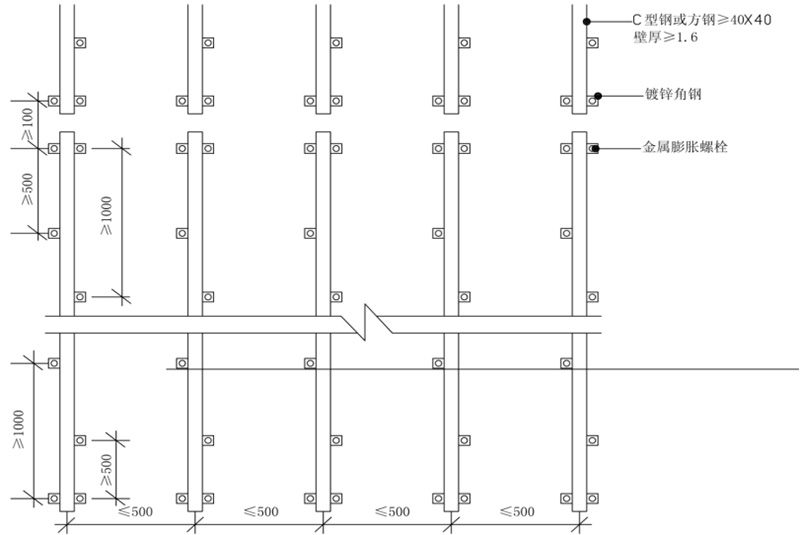

2. The vertical keel spacing for wall panel installation must not exceed 500mm, and air passages must be left between the panels and the wall to prevent moisture and heat insulation.

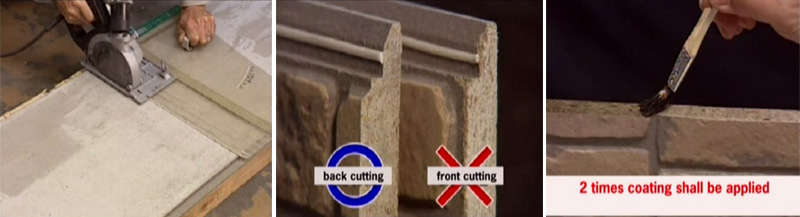

3. When cutting the cement board panels on site, the back of the panels should face upward to prevent the front edge from collapsing. Cutting with water is not allowed. Apply waterproofing agent in time after cutting. The cut panels must be placed flat and installed in time to prevent exposure to the sun and rain to prevent creep caused by stress.

4. The cement board panels must be installed horizontally, and the initial installation must be installed with a water-shedding horizontal board. The wall panels must not be buried underground or placed in water. When installing the wall panels, the initial clamps must be kept horizontal, and the rubber pads must be used to stick to the 30 cm in the middle of the back of the panel. The rubber pads are self-adhesive to the keel between the upper and lower clamps.

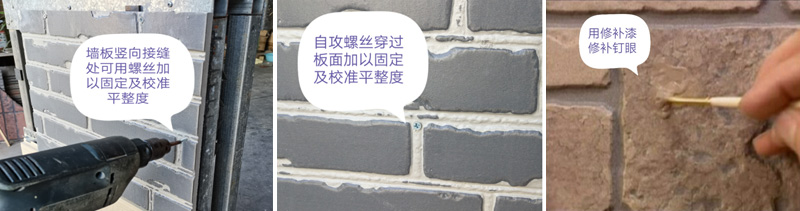

5. When choosing auxiliary materials for the installation of cement board panels, galvanized light steel keels or fireproof and anti-corrosion treated wooden keels should be used, and they should be fixed with anti-rust hangers and self-tapping screws. The keel must be installed flat, and the steel keel hangers should be screwed in place, and the wooden keel hangers should be nailed down 70° with iron nails. If the installation board surface is uneven, it can be corrected with iron nails or screws, and the nail heads should be painted with the same color paint to ensure color consistency.

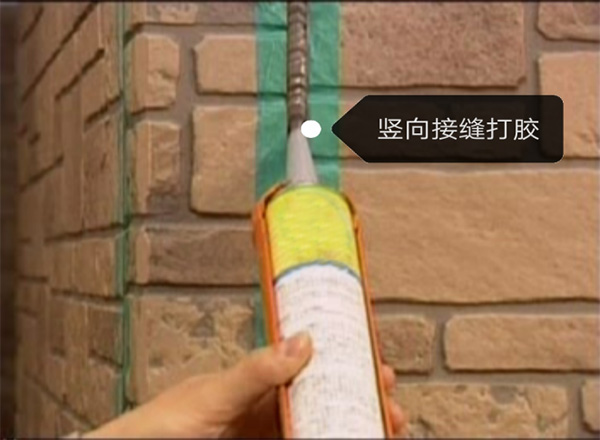

6. A 5mm shrinkage gap must be left between the vertical connections of the boards. To ensure vertical installation and facilitate gluing, aluminum alloy joint strips are placed between the left and right boards. Foam sticks can also be filled in the gaps. Masking tape is pasted on both sides of the gaps before gluing. Weather-resistant and elastic exterior wall sealant should be used for filling the gaps. After applying the glue and smoothing, tear off the masking tape.

7. At the top of the wall, the board can be cut on site according to the height. If the cut board has no tongue and groove, it can be leveled with rubber pads and fixed directly with screws.

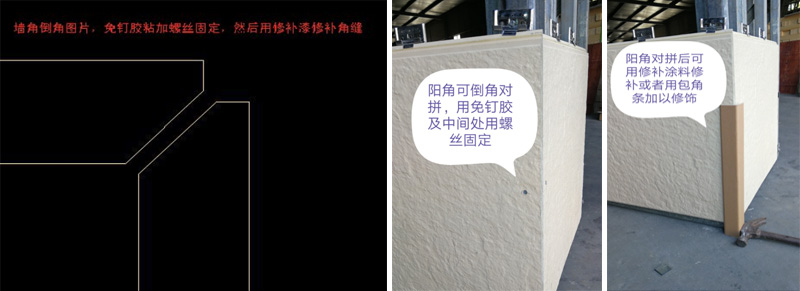

8. The Yin and Yang corners can be directly chamfered with boards and fixed with nail-free glue and screws. They can also be modified with corner strips. Before adding the corner decorative strips, the Yang corners need to be fixed with screws.

9. Design engineers, construction managers, and construction personnel must read this user manual and installation node diagram and master relevant installation knowledge. If you have any questions, please call our engineering and technical personnel for consultation.

Tel:+86 025-52723202 / 025-52723345

Whatsapp:+86 13851543172(张玉萍)/ 13601434378(张静)/ 15077833113(熊志伟)

E-mail:njxrl@njxrl.com